A car usually has about 30 kinds of 50 sets of bearings installed in different rotating parts. In practice, automotive bearings are generally classified according to the installation or use position. Corresponding to the division of automobile into engine, transmission system, steering system and air conditioning system, automobile bearings can be first divided into engine bearings, transmission system bearings, steering system bearings and air conditioner bearings according to the installation position, and then can be further subdivided to each part of the above system and the specific installation position of bearings. Because of the diversity of automobile and bearing design, similar parts of different automobiles often use different component structures and bearing structures. Bearing installation position diagram and corresponding bearing spectrum table can be used to express the bearing installation position in more detail and intuitively, and the internal relationship between parts and bearings can be revealed by giving bearing model, dimension and installation position at the same time.

1 Hub bearing

The main role of hub bearing is to bear and provide accurate guidance for hub rotation, it bears both axial load and radial load, is a very important parts.

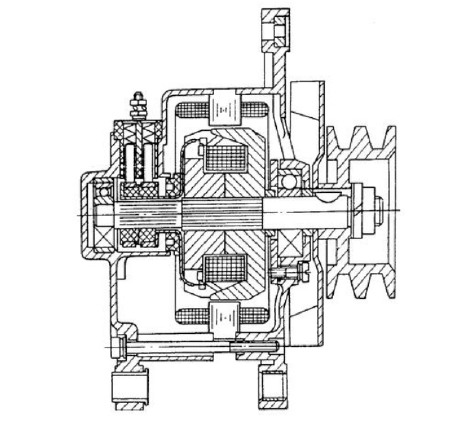

The traditional automobile wheel bearings are composed of two sets of tapered roller bearings or ball bearings. The installation, oiling, sealing and clearance adjustment of bearings are carried out on the automobile production line. This structure makes it difficult to assemble, high cost and poor reliability in the automobile production plant. Moreover, when the automobile is maintained at the maintenance point, the bearing needs to be cleaned, oiled and adjusted. Hub bearing unit is developed on the basis of standard angular contact ball bearing and tapered roller bearing, it takes two sets of bearings as one, has the advantages of good assembly performance, can omit clearance adjustment, light weight, compact structure, large load capacity, for sealing bearings can be loaded into grease beforehand, omit the external hub seal and free from maintenance, and has been widely used in cars. There is also a tendency to gradually expand the application in the truck.

2 Clutch separation bearing

The clutch separation bearing is installed between the clutch and the transmission, and the separation bearing seat is loosely set on the tubular extension of the bearing cover of the first shaft of the transmission. Through the return spring, the convex shoulder of the separation bearing always reaches the separation fork and returns to the final position, and the separation lever end (separation finger) maintains a gap of about 3~4mm.

As a result of the clutch pressure plate, separation lever and engine crankshaft synchronous operation, and the separation fork can only move along the clutch output shaft axial, directly use the separation fork to dial the separation lever is obviously not, through the separation bearing can make the separation lever one side rotation along the clutch output shaft axial movement, so as to ensure that the clutch can engage smooth, soft separation, reduce wear, Prolong the service life of the clutch and the whole transmission system.

3 Generator bearing

There are two kinds of generators in automotive ignition system: shunt DC generator and semiconductor rectifier generator.

Among them, alternator is developing rapidly because of its strong power generation capacity, wide speed range, compact structure, reliable operation and long service life. For generator bearings, to adapt to this development means that the bearing capacity, ultimate speed, rotation accuracy, lubrication and sealing performance and noise performance must be improved.

4 Ventilator bearing

In order to keep the engine at the best working temperature and reduce power consumption as far as possible, modern engines generally use adjustable ventilators. When the traveling air flow and radiation heat dissipation are enough to ensure that they do not exceed the best working temperature, the ventilators are in a stopped state, and when they exceed the best working temperature, the ventilators enter the working state.

The ventilator with intermittent operation has a variety of transmission structures, and different structures of the ventilator have different requirements for bearings. But when installed directly in the ventilator impeller, the biggest problem facing the bearing is to bear a large load and may be high temperature of 150-230 degrees Celsius.

5 tensioning wheel bearings

With the application of high camshaft and overhead camshaft in modern automobile engine synchronous chain drive and gear drive of camshaft have been gradually replaced by toothed belt drive. At the same time, the motor diesel fuel injection pump also adopts synchronous gear belt. In order to facilitate the installation and adjustment of the synchronous gear belt, tension wheel is generally used on the loose edge of the gear belt. In the more complicated gear belt drive, the idler wheel with fixed position is often used on the tight edge of gear belt to increase the covering Angle of the gear wheel or change the position of gear belt.

2023-01-06